>

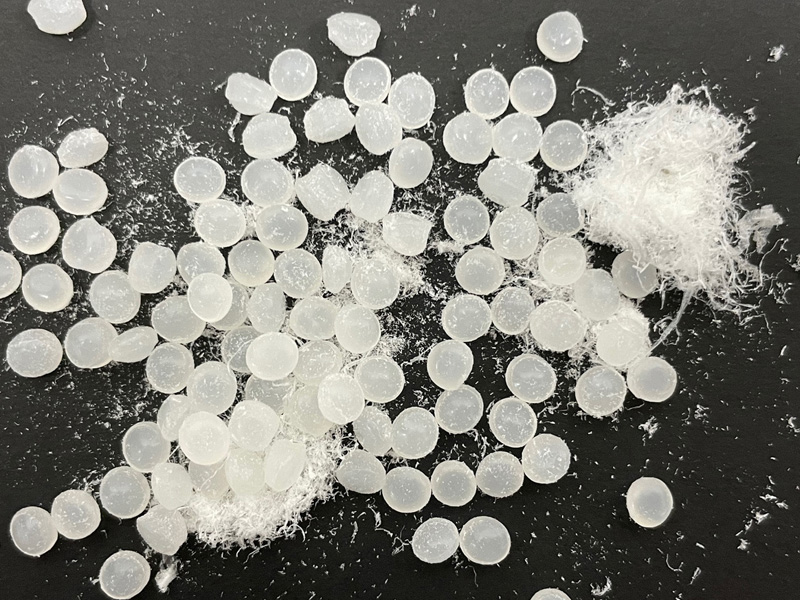

Plastic pellets generate impurities such as dust, streamers, angel hair, etc. due to friction in the conveying line.

When the pellet is transferred at a high speed as in the dilute phase, foreign substances such as streamer or angel hair are generated as the pellet scratches against the pipe,

and fine dust is generated when it is relatively slowly transferred at higher pressures as in the dense phase. In addition,

dust may be generated due to the temperature and the characteristics of the raw materials.

These foreign matters lower the purity of the plastic pellet and cause problems by degrading the quality and performance of the end-product.

It is important to clean the raw material with a dust removal system in the secondary process.

Pre-existing dedusting machines had problems of uneven and unsmooth air supply to the raw materials, raw material agglomeration, clogging of dust, or debris blocking the air supply nozzle.

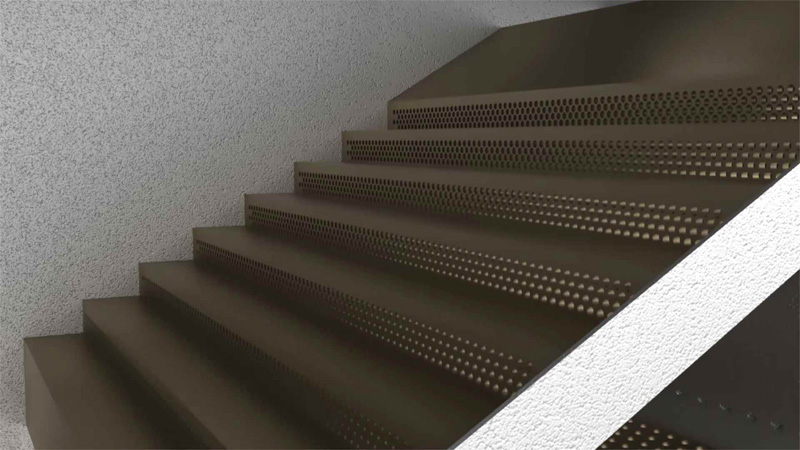

Accordingly, Conep has designed a step wash deck in which raw materials are fluidized to improve the problems of existing facilities and increase efficiency.

The stepped deck has punch holes at every step of the stairs, so air is evenly supplied through the holes for efficient washing, and the innovative arrangement of the

holes can avoid the accumulation and clogging of foreign substances.

In the case of the conventional straight deck, the supply of air was not smooth because the raw material rapidly descended due to acceleration. However,

in case of the Conep’s stepped deck, the raw material descends and collides with the step of the stairs, so that physical desorption is possible.

As the speed of descent decreases, the air supply is smoother, and the dust separation efficiency is excellent.

The standard X-dusters for plastics manufacturers and compounders.

X-dusters' XD-series is the most commonly applied model for the process.

The raw material flows into the inlet is evenly distributed to the two stepped washing decks and undergoes a dust removal process once more in the stepped washing

deck at the bottom. This model can be applied to any process requiring a single inlet/outlet design.

The model of X-dusters can be designed differently depending on the shape of the pellet and the type and characteristics of dust.

Custom design is available based on customer’s individual requirements.

We provide optimal design to meet individual requires of customers. By thoroughly analyzing the characteristics of raw materials and considering the entire process, our expert team provides optimal solutions.