>

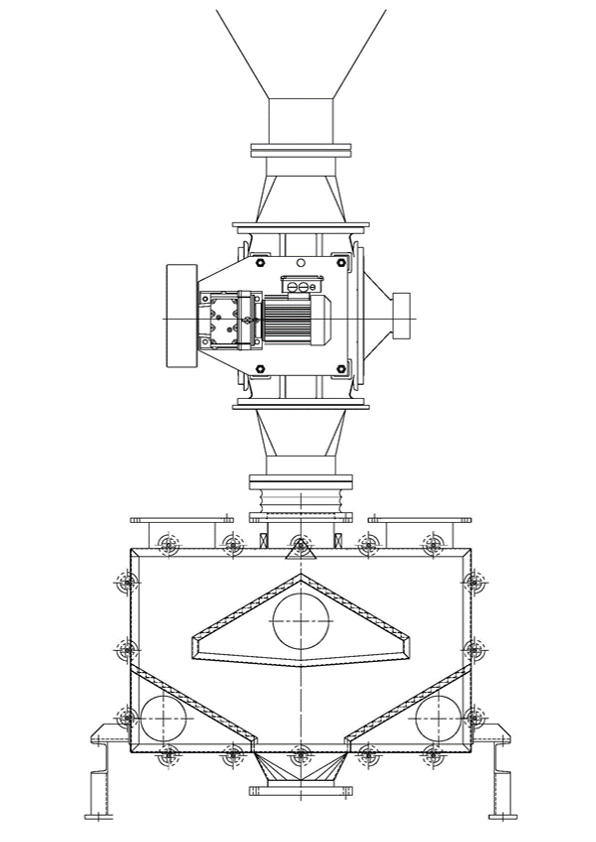

The Elutriator is located at the end of the Pneumatic Conveying system and acts as pre-air cleaners. In order to reduce the inflow of particulate matter (PM) into the downstream separating devices (in this case, X-dusters), it is a raw material mainly in the process because it has a function of separating large abrasive particles such as snake skin, streamer, and angel hair. It is used for separating foreign substances from and. Based on our multi-faceted and deep understanding of pneumatic conveying systems and air pollution control systems, we are providing elution technology suitable for processes that require a powder conveying system.

Conep has been devoted to research for a long time to extract the problems of existing technology and design efficient and economical facilities.

And finally, based on basic science principles and creativity, we succeeded in developing our own elutriator.

Conep focused on the baffle plate. We judged that the shape of the baffle plate, which is the key section where the separation of raw materials and foreign substances occurs due to inertia,

is the most important factor in maximizing dust efficiency.

The raw material and foreign matter injected into the inlet by pneumatics fall in a conical shape along the inclined plate in the air. The raw material quickly falls out of the

baffle plate edge due to the slope of the baffle plate, and the separation area is limited to the baffle plate edge.

In order to solve this problem, Conep expanded the separation area by envisioning the baffle plate in a step shape.

The raw material falling from above collides with the upper part of the stairs and causes a physical desorption reaction,

and dust is collected through the gas outlet by securing a separation area above the slope of the stairs by the airflow induced from the perforated plate on the side of the stairs.

In addition, to ensure that the raw materials do not stay on the stairs, the slope of the stairs is designed with a high understanding and know-how on the characteristics

of Conep's raw materials so that the raw materials constantly reach the separation area. The perforated plate is limitedly perforated only on the side of the stairs,

preventing pieces of the product or the raw material itself from getting stuck.

In general, the elutriator is a facility used to separate large-sized particles. It is possible to remove about 60% or more of dust with small particles,

and about 90% of the relatively large and thin streamer or Angel Hair. Reduces the dust concentration from 400 to 800 ppm to less than 100 to 200 ppm. However, in order to keep pace with

the increasing customer demand for product quality and purity, elutriator alone may not be enough. In the case of products with a high proportion of fine particulate matter due to the nature

of the raw material, the removal efficiency of close to 100% can be achieved through Conep’s X-dusters. X-dusters removes less than 50ppm of dust with strong magnetic field and air inflow,

and the efficiency reaches more than 85%. In the case of Streamer, it can remove up to 99%, so you can meet near-perfect clean raw materials.

In addition, Conep's rotary feeder, a downstream device of elutriator, delivers clean raw materials easily and reliably through Conep's patented air sealing technology.

As air does not leak, jamming and cracking do not occur, and air pressure is maintained, which is excellent for transfer to the next process.