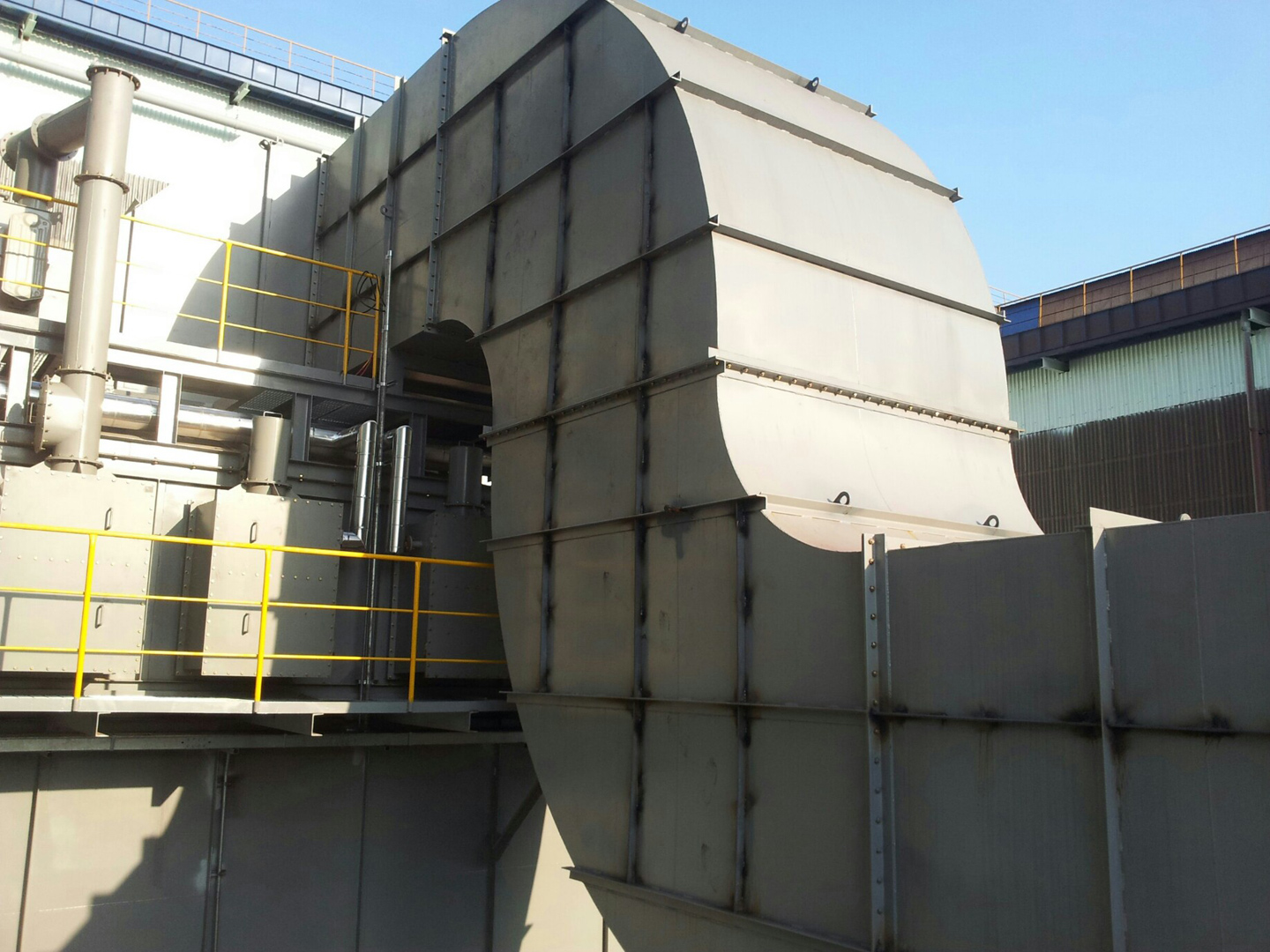

Wet Electrostatic Precipitator

Conep's patented collecting plate with curves and pockets utilizes centrifugal force and pocket blocking,

so it is highly efficient in collecting particles without re-scattering them even at a high velocity, making it compact and economical.

In order to maximize the benefits of WESP, Conep installs a patented pretreatment device on the front of the WESP, which combines the functions of the Venturi Scrubber and the Mist Eliminator.

Sufficient cleaning water is supplied to the pretreatment device to remove particles from the gas stream. In the case of unremoved particles,

waster is attached to their surface to optimize the electrical properties inside the WESP, increasing the removal efficiency.

Water droplets entering the WESP with other particles are also removed from the collecting plate using an electric charge and run down. At this time,

the collected particles are allowed to flow down with the water and be discharged to the outside so that the WESP can be cleaned continuously during operation,

and high removal efficiency is maintained at all times.

ㆍPetrochemical industry

ㆍSteel mill, melting furnace

ㆍBoiler, incinerator

ㆍRemoval of gasoline salts (SO3 Mist, Oil Mist, etc.)

ㆍDyeing, synthetic resin manufacturing process

ㆍFast-pass flow rate of over 2.0 m/sec

ㆍMaintaining high dust collection efficiency by continuous cleaning

ㆍHigh efficiency without ash scattering

ㆍMinimized maintenance by fixing the upper and lower discharge parts

ㆍCompact design and low investment cost